Condition monitoring solutions for marine and offshore

SPM Marine & Offshore provides condition monitoring solutions that help shipowners and operators avoid sudden failures and maximize equipment lifetime. Our technology is installed onboard more than a thousand vessels and is widely used in condition-based maintenance programs across the marine and offshore industry.

Maintenance on board vessels has traditionally been based on the running time of equipment. Increasing demands on the environment, reliability, and ship safety have led classification societies to widely adopt condition monitoring, making it now an option for most vessels.

Knowing the condition of your machinery is crucial to avoid sudden failures and to extend equipment lifetime. By utilizing our condition monitoring instrumentation and methods, operators can gain timely failure prediction and detection, which reduces the required workforce and spare part inventory, ultimately helping to increase profit.

“We were looking for a supplier who could solve the specialized problems of our clients regarding slow turning machinery. We also wanted a software platform that was ‘analysis friendly. But the most principal factor in our decision to buy the Leonova Diamond was the HD technology."

“We were looking for a supplier who could solve the specialized problems of our clients regarding slow turning machinery. We also wanted a software platform that was ‘analysis friendly. But the most principal factor in our decision to buy the Leonova Diamond was the HD technology."

Bárður Heinason, Machine technician, MEST, Faroe Islands

Solutions for the marine and offshore industries

Since the beginning, SPM has expanded its range of portable instruments, online systems, and accessories for shock pulse monitoring of rotating machinery such as:

- Pumps

- Fans

- Turbochargers

- Azipods

- Electrical motors

Vibration monitoring equipment is used where problems such as alignment, impeller issues, gear faults, or balancing problems occur. On slowly rotating machinery, the SPM HD® technique provides high signal quality and precise spectrums for analysis.

Portable instruments

Intellinova online systems

HD Technologies

Transducers and transmitters

Certified for the marine and offshore industry

Condition-based maintenance in the maritime industry

More efficient use of crew resources

The trend leans towards larger vessels operated by smaller crews. Operating large ships with a relatively small crew puts focus on how to use working hours more effectively. We can learn from condition-based maintenance (CBM) strategies implemented by the land-based industry exposed to international competition and adopt this way of working to the maritime industry. A big part of the maintenance work onboard vessels is, in fact, unnecessary and a product of tradition and previous demands by the class.

Challenges with traditional maintenance practices

The combination of unskilled labor and inspections by classification societies of machines stripped for visual inspections have contributed to the extreme workload in many machine rooms. The redundant machines are installed for safety but are mainly used to compensate for the problems this maintenance approach gives.

How condition-based maintenance works onboard

CBM is routine measurements, and inspections carried out by a selected crew trained to evaluate the results and determine possible corrective maintenance. The redundant equipment is included in the inspection to ensure that they work when needed for safety reasons. The condition monitoring software can be connected to the maintenance management system to issue work orders and get the action reported back into the system automatically. The machines are prepared with adapters and transducers for ensuring quality readings. Critical equipment like turbochargers can be equipped with online systems for extra protection.

Value of condition information

The condition information is used to get an early warning for replacing parts before failure. The readings can also be used for class inspection as an alternative to opening up machines for inspections.

Benefits of condition-based maintenance for operators

CBM increases reliability and requires fewer staff hours by eliminating unnecessary maintenance caused by time-based inspections and the extra work that catastrophic failures give. The work can be planned and give the crew stable working hours. Also, there is a reduction in spare part consumption, allowing a smaller stock and making the number crunchers happy.

Application solution: Turbo charger

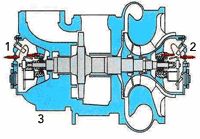

Shock pulse transducers installed in the bearing housings, both on the turbine and the compressor side, are connected by coaxial cables to a multichannel measuring and display module. A vibration sensor monitors the overall movement. The readings can also be captured with a handheld unit, e.g., Leonova Diamond or Leonova Emerald. You get an instant, user-friendly condition evaluation on a green-yellow-red scale. The system gives immediate results such as maximized uptime, increased profitability, and reduced cost, etc.

The concept of air compression and expansion has been used in various applications: gas turbines, steam turbines, wind energy, turbocharging of diesel engines, and is commonly used in the maritime industry.

A turbocharger comprises a turbine and a compressor, connected by a common shaft supported by a bearing system.

The turbocharger converts waste energy into compressed air, which it pushes into the engine. This allows the engine to produce more power and torque and improves the combustion process's overall efficiency.

The turbocharger has two bearings, one on the compressor side and one on the turbine side. The bearings are either of roller bearing type or sleeve bearing type.

Turbocharger breakdowns are very costly. Direct costs are primary and secondary material damages. Indirect costs are off-hire of the ship, penalties due to late arrival to port because of decreased speed, badwill in front of passengers, etc. Therefore, condition monitoring is essential when it comes to turbochargers and planning their maintenance to eliminate any unplanned stops.

Typical faults and trends

While in good condition, turbocharger bearings produce very stable shock pulse readings. Due to the high rpm, the fatigue of these bearings results in a fairly rapid damage development. A few weeks´ warning time can be expected, but it is advisable to replace the bearing at the first opportunity after an increase in the shock level. Vibration above all increases on the turbine side when the compressor is fouled and needs cleaning. Combustion residues on nozzle vanes and turbine blades cause a considerable drop in compressor efficiency.

Bearing damage

The bearing can be damaged due to normal wear, poor lubrication oil, incorrect mounting, etc. If the turbocharger runs until the bearing breaks down due to any of the above reasons, this will cause the turbocharger to stop, and the bearing will have to be replaced before startup. Bearing damage might also cause secondary damages to the turbine and the compressor.

Rotor imbalance

Rotor imbalance means that the turbocharger starts to vibrate. This is because the blades have dirt deposits causing these vibrations. If the turbocharger is run towards a rotor breakdown, this will cause the turbocharger to stop. The rotor will have to be replaced, and most probably, secondary damages will have to be fixed.

The solution

1) Turbine bearing 2) Blower bearing 3) Turbine vibration

A breakdown is very costly, mainly due to material costs. The time from worsened condition to a breakdown is much shorter than many other applications due to the very high speed at which turbochargers are run. An online solution is, therefore, often preferred when monitoring the condition of turbochargers.

Suggested methods

Roller bearing types

SPM monitoring of the bearings with the SPM® method. Vibration monitoring on the housing for measuring the impeller condition.

Sleeve bearing types

Vibration monitoring

For trending and alarm handling, SPM Instrument supplies units that give 4-20 mA output to connect to local PLC. A solution with the Condmaster® Ruby software can also be implemented.