Condition monitoring of engine room machinery

Condition monitoring for engine room machinery varies depending on criticality and accessibility. Some equipment is best monitored through periodic measurements with portable instruments, while others require continuous monitoring with online systems to ensure repeatable and reliable data.

Continuous and portable condition monitoring

Machinery that operates under fluctuating conditions should be measured continuously to achieve reliable trending. In most cases, a complete condition monitoring system on a vessel includes a combination of:

- Portable instrumentation

- Wireless sensors

- A continuous vibration and oil condition monitoring system

Long experience and extensive testing form the basis for selecting suitable equipment and designing these installations.

Typical machinery included in a vessel CBM program

- Electrical motors

- Gearboxes

- Diesel generators

- Turbochargers

- Compressors

- Pumps

- Fans

- Purifiers

- Hydraulic Power Units

Leonova Diamond

Leonova Diamond® is an advanced and powerful data analyzer for high-efficiency measuring routes in rough industrial surroundings.

Intellinova Parallel EN

Intellinova® Parallel EN is a powerhouse of functionality and performance, ideal for condition monitoring of industrial equipment with high availability demands.

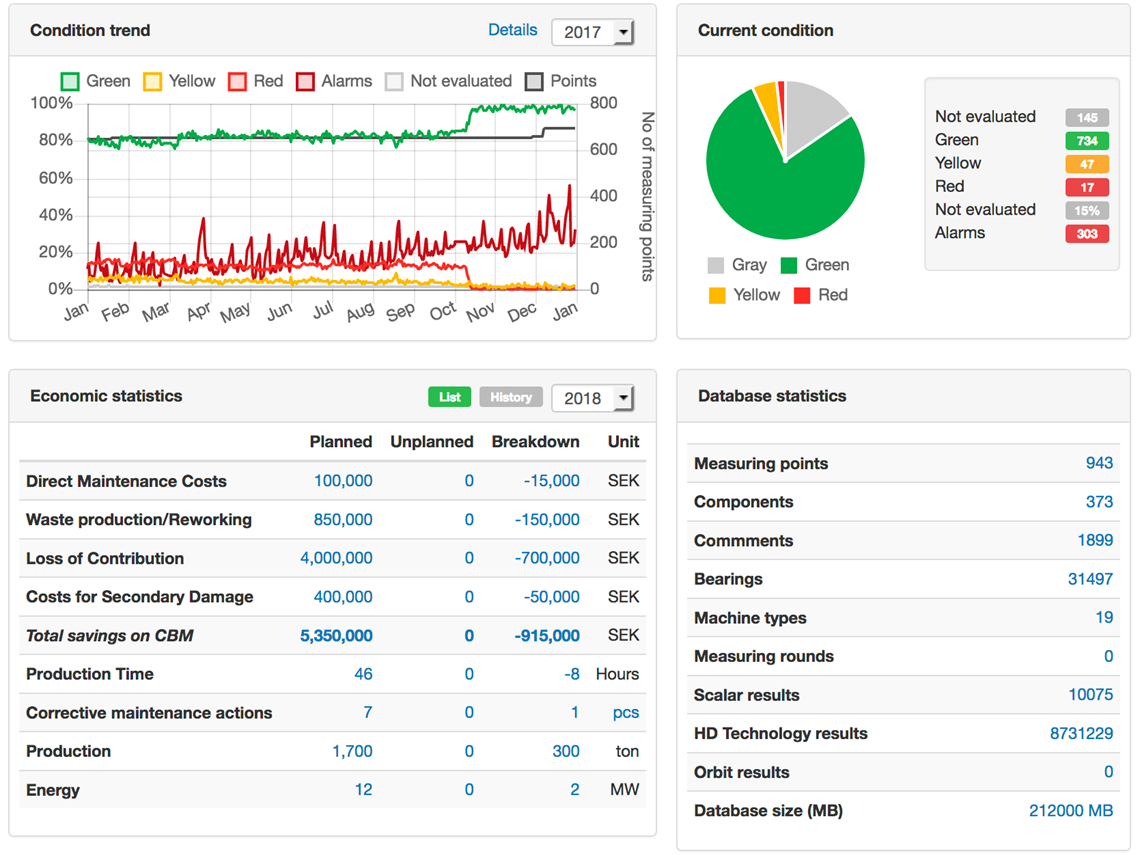

Condmaster Ruby

At the heart of an SPM condition monitoring solution is the powerful Condmaster® Ruby software, containing the expert knowledge needed to evaluate and assess machine condition.