Shaft alignment

The purpose of shaft alignment is to prevent excessive vibration and the premature failure of machine parts. Quite often, bad machine condition can be obvious, but repairs are made without correcting alignment faults, or removing the underlying causes of misalignment such as poor foundations, excessive temperature gradients, strain from connected pipes, etc.

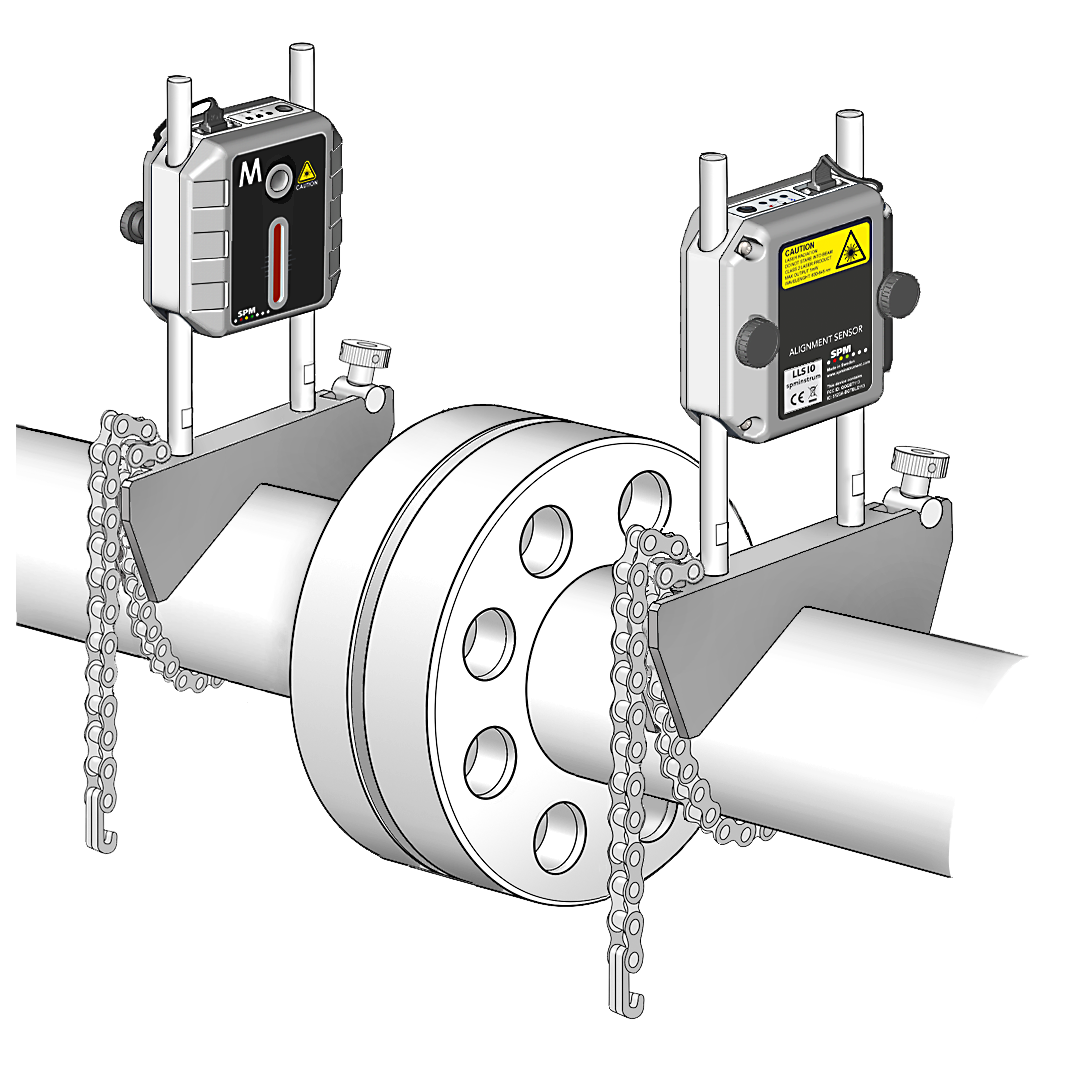

High-precision alignment sensors

Shaft alignment with the LineLazer alignment sensors is an optional function in Leonova Diamond® for quick and easy shaft alignment, with either limited or unlimited use. As an alternative to using portable instrumentation, alignment can also be performed with the LineLazer app installed on any device of your choice. The function is user-friendly and easy to learn.

Shaft alignment is the process of adjusting the relative position of two coupled machines such that the centerlines of the respective shaft form a straight line when the machine is running at normal operating temperature. Alignment is achieved by moving the front and/or back feet of one machine up, down, and sideways, until the shafts are aligned within required tolerances.

The alignment sensors measure the position of the shafts compared to the centerline. Using digital signal processing, the sensors easily and automatically distinguish from interfering light sources. High-precision digital CMOS linear image sensors provide maximum accuracy. Dual-axis, high-precision inclinometers measure the angle of rotation of both alignment sensors at all times, allowing measurement in fully automatic mode with much less than a half-turn of the shaft.

Shaft alignment with Leonova Diamond

The Leonova Diamond instrument is the control and display unit, with a powerful processor that enables very short calculation times. A user-friendly graphical interface guides the user through the entire alignment procedure. Automatic calculations and instant correction and alignment data result in perfect shaft alignment. Leonova also produces a log file with all alignment data for printing a report.

Measurement programs:

- Alignment of horizontally mounted machines (automatic measurement or manual prompts)

- Alignment of vertically and flange mounted machines

- Soft foot measurement

- Compensation for thermal growth

- Feet lock function

- Shaft alignment log

Shaft alignment with the LineLazer app

With the LineLazer app, getting the work done is easier than ever. The app guides the user through the entire alignment process in an intuitive manner, using a visually appealing and intelligible 3D graphical interface. The possibility to rotate the virtual machine for a live 3D view from any direction facilitates understanding, while the continuous sweep function - enabling measurement during rotation - saves considerable time and effort.

Functions:

- Responsive design

- Continuous sweep

- Visual amplification of misalignment

- Soft foot check

- Feet lock

- Thermal growth compensation

- Tolerance checks

- Demonstration mode