Oil Quality Sensor

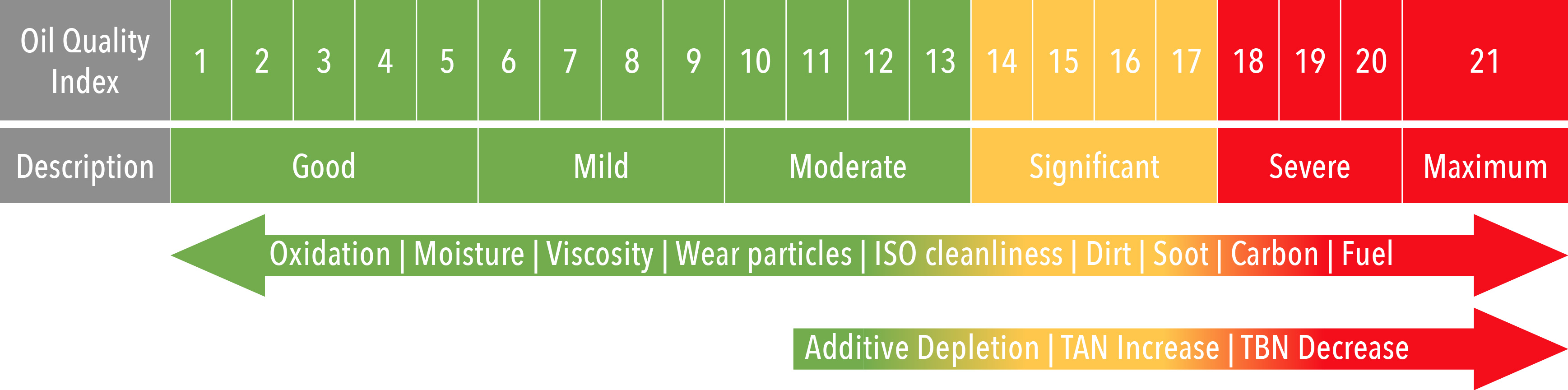

The Oil Quality Sensor (OQS) puts you in control with real-time monitoring of oil degradation and water ingress. Expensive oil changes are now based on oil condition, not historical schedule.

Features

The requirement to implement an effective monitoring and maintenance program for lubricants in critical plant machinery has never been greater. With the escalating price of crude oil and the vast improvements that are being seen in the quality of lubricants available today, it is more important than ever for organizations to ensure that they are maximizing the service life of the oil used. Monitoring oil condition is clearly fundamental to understanding the optimal time to change. Change too early and the cost is significant – change too late, and the costs can be even greater!

The sensor is a live, highly flexible, and cost-effective condition-based monitoring solution designed to be permanently installed within any lubrication system on any type of machine. Over 60 times more sensitive to oil contamination than any other dielectric constant measuring sensor, it provides real-time monitoring of water ingress and oxidation levels.

Measuring results will be stored in Condmaster Ruby and presented in trend graphs with alert limits.

Benefits

- Reduced maintenance costs

- Extended oil change intervals

- Scheduled downtime intervals for increased productivity

- Reduced waste oil cost

- Improved equipment reliability

- Low-cost investment tool

- Reduced carbon footprint

- Reduced total cost of ownership