Measure the straightness of bore center lines, bearing journals, and other cylindrical objects with the Easy-Laser® XT950 Bore alignment system.

The Easy-Laser® XT950 Bore alignment system is used for the precise alignment of bore center lines, bearing journals, and cylindrical objects. Designed for applications such as engines, compressors and gearboxes, it accurately measures bore sizes between 80 and 500 mm (3.15–19.68 inches).

Flexible mounting options

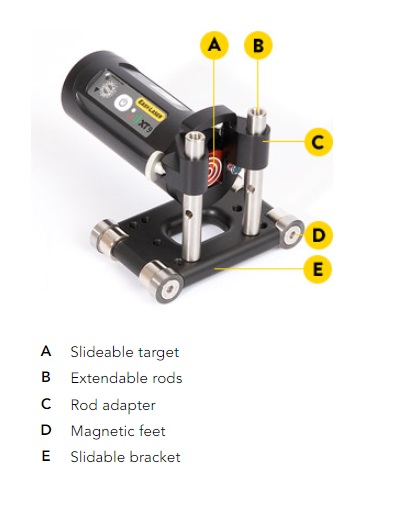

Different brackets makes the system highly versatile, and makes it easy to mount the detector in bores of varying widths. The magnetic feet hold the detector perfectly for stable and precise measurements.

Intuitive user experience

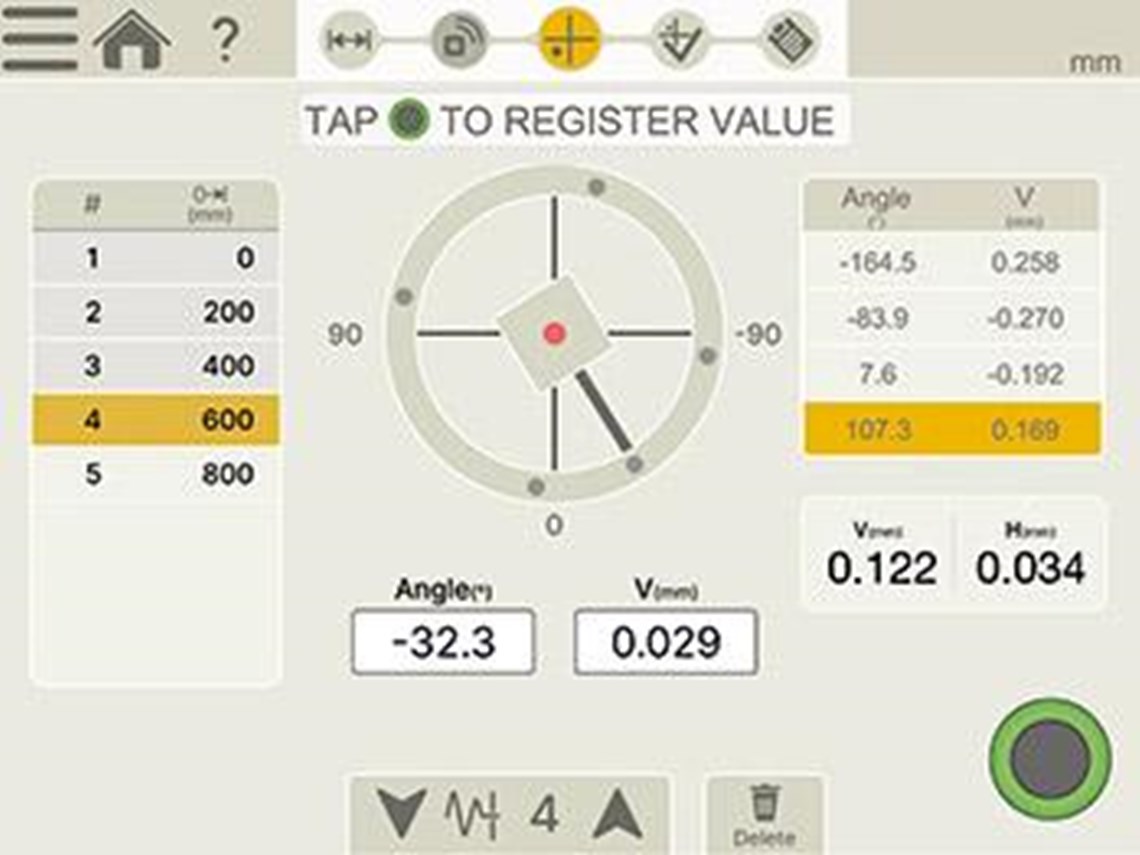

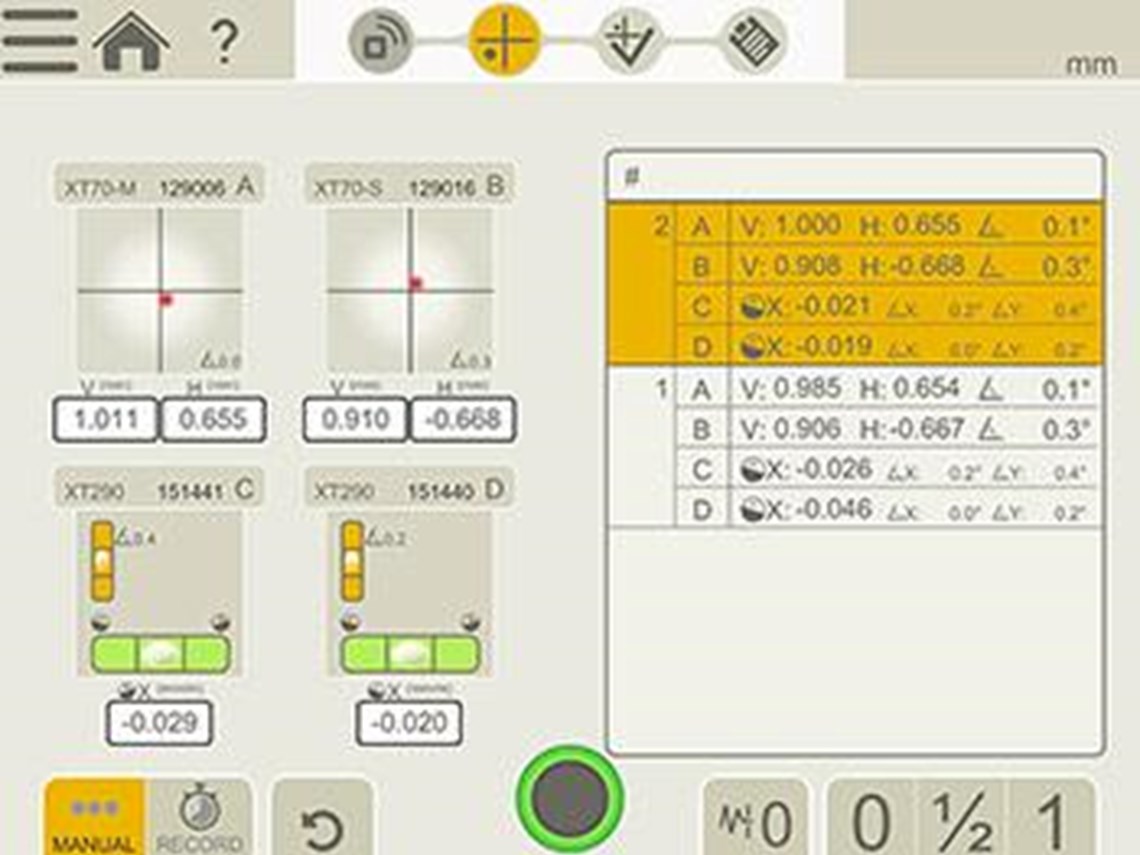

The Bore Center program in the XT app (coming soon) guides the user through the entire measurement process, contributing to simple operation. The system automatically calculates the bearing journals' positions in relation to each other horizontally and vertically. You can evaluate the results with different best-fit calculation methods, analyze different choices of reference points, and set tolerance values.

High precision over long distances

Each component is crafted for maximum accuracy and stability, and ensures reliability with a resolution of 0.001 mm (0.05 mils) over distances up to 40 m (130 feet). This makes the system suitable for both manufacturing environments and field services.

Features

Measurement programs

The featured programs below are the most commonly used with this system. Please click here for a complete overview of possibilities.

*=accessories needed

Bore center

Values - Extended applications

Technical overview

Display unit

| Name: | XT12 |

| Type of display/size: | 8" LCD capacitive multi-touch colour display |

| Internal battery (fixed): | Heavy-duty Li-Ion chargeable |

| Connections: | USB A, USB C, Charger, AV |

| Operating temperature: | −10 to 50 °C |

| Storage temperature: | −20 to 50 °C |

| Communication: | Wireless technology, Wi-Fi |

| Relative humidity: | 10 to 95% |

| Camera: | 13 Mp, with diode lamp |

| IR camera (optional): | FLIR LEPTON® (0–450 °C, 32–842 °F) |

| Help functions: | Built-in manual |

| Environmental protection: | IP class 66 and 67 |

| Housing material: | PC/ABS + TPE |

| Dimensions (WxHxD): | 269 x 190 x 49.4 mm |

| Weight: | 1400 g |

| Operating time: | Up to 16 h continuously |

Laser Transmitter

| Name: | D75 |

| Part no: | 12-0075 |

| Type of laser: | Diode laser |

| Laser wavelength: | 630–680 nm, visible red light |

| Laser Safety Class | Class 2 |

| Adjustable modulation | 5, 32 KH |

| Output | < 1 mW |

| Beam diameter | 6 mm [1/4"] at aperture |

| Working area, range | 40 m [130'] |

| Type of battery | 1 x R14 (C) |

| Operating time/battery | approx. 15 h |

| Laser adjustment | D75: 2 ways ±2° (± 35 mm/m) |

| Housing material | Anodized aluminium |

| Dimensions | WxHxD: 60x60x120 mm [2.36x2.36x4.72"] |

| Weight |

|

Detector

| Name: | XT9 |

| Part no | 12-1350 |

| Communication | BT wireless technology |

| Type of detector | 2 axis PSD 20x20 mm [0.78" sq] |

| Resolution | 0.001 mm [0.05 mils] |

| Measurement accuracy | ±1µm ±1% |

| Inclinometers: | 0.1° resolution |

| Thermal sensor | ± 1° C accuracy |

| Environmental protection | IP class 66 and 67 |

| Internal battery | Heavy duty Li Ion rechargeable |

| Operating temperature | -10–50 °C [14–122 °F] |

| Housing material: | Anodized aluminium |

| Dimensions (WxHxD): | Diameter 44 mm [1.73"], length 100 mm [3.93"] |

| Weight: | 194 g |

System parts

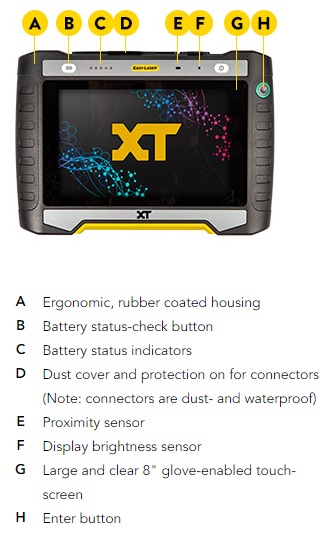

Display unit XT12

Rugged, robust, industrial grade tablet with wear resistant rubberized protective coating. IP66 and 67, dust- water- and shockproof. As standard a 13 MP camera for documentation is built-in, but you can also choose a model with IR camera added.

Glove-enabled touch screen

A large 8", glove-enabled touch-screen makes the information clear and the app easy to use. You can check battery status also when the unit is turned off .

Heavy-duty rechargeable battery for very long operatong times; up to 16 hours. Fastening points for shoulder strap (included).

*The camera can be removed if security reasons require.

Features

- Robust, rubber-coated design, IP66/67.

- Large 8" glove enabled touch screen.

- IR camera for thermal images (optional).

- 16 hours of operating time.

Detector XT9 with slide brackets (3 sizes)

Set of three slide brackets with extendable rods for different bore diameters.

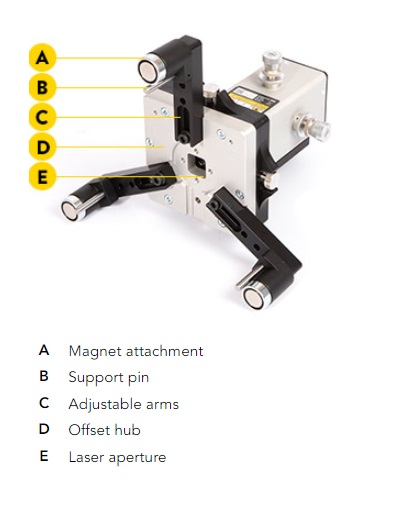

D75 Laser transmitter with arms

The laser transmitters’ rigid design assures highest measurement accuracy. The bracket has three sets of adjustable arms with magnets to fit different diameters. The arms can be mounted with 120° incremental or all three downwards, depending on if it will be mounted in a full bore or half bore. The transmitter can be mounted to point the laser beam either away from, or through, the offset hub.

Fine adjustment of the laser beam in horizontal and vertical direction is made very easy with the offset hub.

A complete system contains

- 1 Laser transmitter D75

- 1 Detector XT9

- 1 Offset hub with counterlock for D75

- 1 Arm kit with magnets

- 1 Set of rods 4x75 mm

- 1 Set of rods 4x120 mm

- 1 Slide bracket Small

- 1 Slide bracket Medium

- 1 Slide bracket Large

- 1 Bracket with rotatable bore probe, XT

- 1 Target for detector rough alignment

- 1 Axial support for slide brackets

- 1 Rod adapter with built-in target C–C 56 mm

- 1 Rod adapter with built-in target C–C 40 mm

- 1 Slide bracket, 25 mm width

- 1 Battery charger (100–240 V AC)

- 1 USB memory stick with documentation

- 1 Measuring tape 5 m

- 1 Hexagon wrench set

- 1 DC to USB adapter, for charging

- 1 DC split cable for charging

- 1 Cleaning cloth for optics

- 1 Carrying case XT Linebore WxHxD: 546x432x244 mm [21.5x17.0x9.6"]

Optional:

- XT12 Display unit, with or without IR camera

Examples of accessories for XT950:

- 12-0553 Bore bracket adapter plate

- 12-0314 Detector arms Linebore

- 12-0187 Magnetic bracket for D75

- 12-0282 Set of extension arms

- 12-0580 Axial extension arms

- 12-0990 Adjustable magnet for offset hub arms